- Home

- Products

JOBORN is specialized in manufacturing stone processing equipment including infrared bridge stone cutting machines, stone cutting saws, stone polishing equipment, stone calibrating equipment and more. Our equipment can process many kinds of stone including granite, sandstone, artificial stone, limestone, cave stone, marble plate and waste blocks. With 20 years of stone equipment processing experience, we can combine new technologies with the needs of customers quickly, providing high quality stone cutting and grinding equipment to customers all over the world.

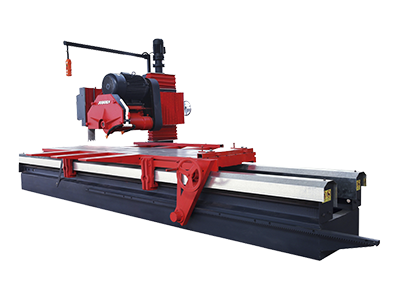

Stone Cutting Bridge Saw

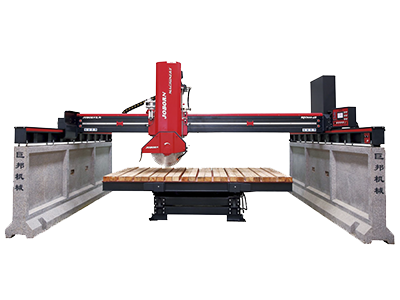

Stone Cutting Bridge Saw SVI Stone Cutting Saw, Granite Cutting Bridge Saw

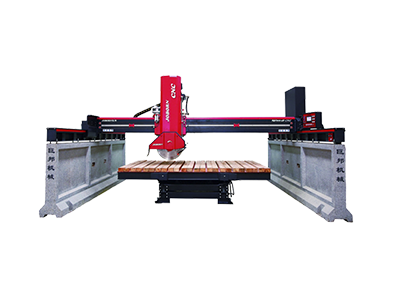

SVI Stone Cutting Saw, Granite Cutting Bridge Saw CNC Stone Cutting Bridge Saw

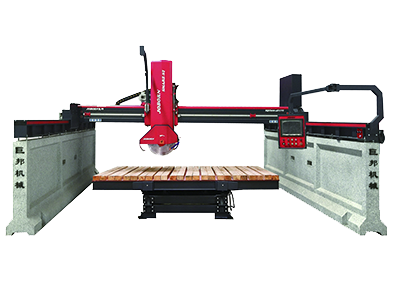

CNC Stone Cutting Bridge Saw 45 Degree Bridge Stone Cutting Saw, Granite Cutting Saw

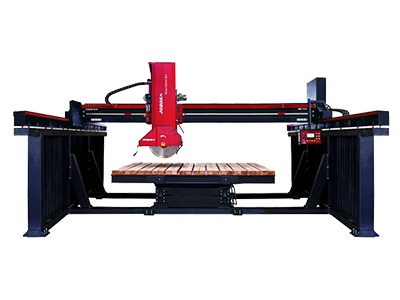

45 Degree Bridge Stone Cutting Saw, Granite Cutting Saw Middle Block Cutting Bridge Saw, Marble and Granite Cutting Saw

Middle Block Cutting Bridge Saw, Marble and Granite Cutting Saw Block Cutting Bridge Saw, Marble and Granite Cutting Saw

Block Cutting Bridge Saw, Marble and Granite Cutting Saw Block Cutting Bridge Saw, Pro Series

Block Cutting Bridge Saw, Pro Series Manual Stone Cutting Machine

Manual Stone Cutting Machine SPG Series Automatic Granite Polishing Machine

SPG Series Automatic Granite Polishing Machine SPG plus Series Granite Polishing Machine

SPG plus Series Granite Polishing Machine SPM Series Automatic Marble Polishing Machine

SPM Series Automatic Marble Polishing Machine SPM Pro Series Automatic Stone Polishing Machine

SPM Pro Series Automatic Stone Polishing Machine SPM Plus Series Automatic Marble Polishing Machine

SPM Plus Series Automatic Marble Polishing Machine Manual Stone Polishing Machine

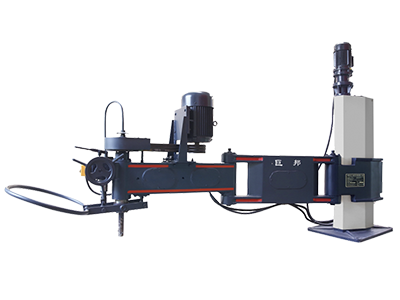

Manual Stone Polishing Machine Automatic Stone Profiling Machine

Automatic Stone Profiling Machine Automatic Gantry Calibrating Machine

Automatic Gantry Calibrating Machine Stone Continuous Calibrating Machine

Stone Continuous Calibrating Machine

The advantages of our products

- JOBORN Machinery uses a series of high standard components such as German BOSCH converters, OMRON switches, and Taiwanese Sansheng hydraulic systems to improve the working performance of our stone cutting machines.

- The machine adopts a microcomputer control system and human-machine interface and is equipped with high-precision rotational encoder and infrared laser marker.

- The cutter moves left and right is controlled by an imported converter, which can adjust the speed according to the stone material.

- Up and down movement is controlled by a double hydraulic system. The guide is wear-resistant and beautiful adopting a chrome plating guide column + wear-resistant guide sleeve.

- Multi-layer sealing is designed with a guide sleeve to seal components from water, dust and oil, increasing the service life.

- High efficiency energy-saving motor is adopted for the main power system to save costs throughout the lifetime.

- Welded with super-heavy large structural sections, the worktable has larger load capacity and is more durable compared to common worktables.

- With the key parts all produced with high quality, the machine has the advantages of high cutting efficiency, high cutting precision, low cost, good stability and easy operation, so it is suited for cutting high value large granite and marble plate.