- Home

- Products

- Stone Cutting Machine

- Stone Cutting Bridge Saw

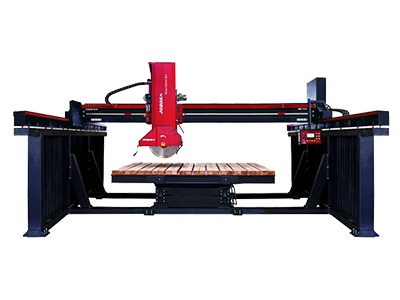

Stone Cutting Bridge Saw

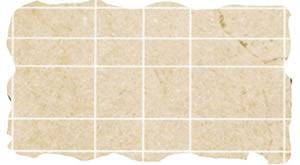

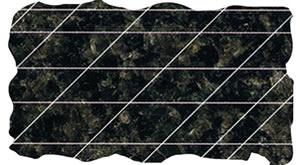

- Materials suitable for cutting: stone slab such as granite, sandstone, artificial stone, limestone, travertine and marble.

- Size suitable for cutting: 3.2m x 2m

- Weight: stone slab with less than 3 tons

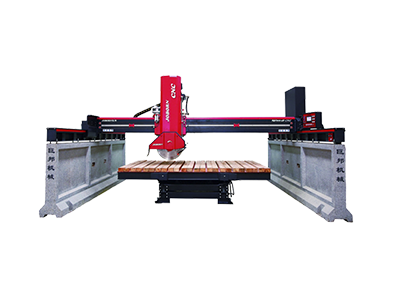

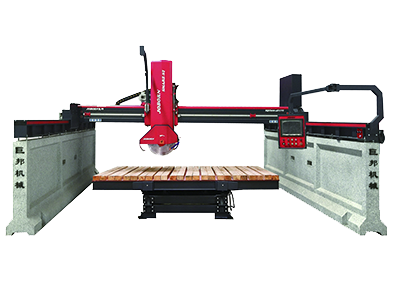

The stone cutting bridge saw is easy to operate and achieve precise cutting thanks to its microcomputer control system and the interface. The head is positioned by the infrared laser alignment device according to the cutting line. The maximum diameters of the blades are 450 mm, 600 mm and 700 mm, and the corresponding maximum cutting depth is 100 mm, 180 mm and 230 mm.

Cutting effect Specifications| Appellation | Unit | SQC450-4D | SQC600-4D | SQC700-4D |

| Max. disc diameter | mm | Φ450 | Φ600 | Φ700 |

| Max. lifting stroke | mm | 220 | 350 | 470 |

| Worktable size | mm | 3200×2000 | ||

| Worktable rotation range (Optional) | 0°,90° / 0°~360° (Set up by each 45°) | |||

| Worktable turn-over degree | 85° | |||

| Max. processing height | mm | 100 | 180 | 230 |

| Water consumption | m³/h | 3 | ||

| Power of main motor | kW | 15 | 18.5 | 22 |

| Total power | kW | 21 | 24.5 | 28 |

| Dimension (LxWxH) | mm | 6000×4800×3200 | 6000×4800×3200 | 6000×4800×3400 |

| Weight | kg | 5700 (6500kg includes steel stand) | 5800 (6600kg includes steel stand) | 5900 (6700kg includes steel stand) |

The worktable can be rotated or tilted. Designed with multi-layer sealing, the guide bush can proof water, dust and oil, which greatly improves its service life. The key parts of the bridge stone cutting machine are all from high quality suppliers. The stone cutting machine has high cutting efficiency, high cutting precision, high stability and easy operation, which is suitable for all kinds of stone processing factories.

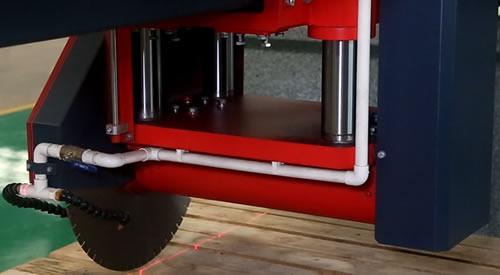

Use infrared laser alignment device to determine the position

Use infrared laser alignment device to determine the position

The worktable can be rotated or tilted

The worktable can be rotated or tilted

High precision chrome-plated guide pillar+ wear-resistant guide bush

High precision chrome-plated guide pillar+ wear-resistant guide bush

Workflow

Details of the equipment

With a humanized human-computer interaction interface, the stone cutting bridge saw is simple to operate and highly precise.

Controlled by the German Bosch frequency converter to go left and right, the head can adjust speed according to different materials.

With the blade controlled by dual hydraulic system made in Taiwan to go up and down, the bridge saw works stably.

With the worktable welded from ultra-heavy structural sections, the worktable has a larger load capacity and is more durable compared to common worktables.

With an energy-efficient main motor, the bridge saw is powerful and electricity saving, which saves cost for customers for long time use.

Designed by a professional Italian industrial design team, it features special car-use paint, spray paint technology, multi-layer antirust and anticorrosion treatment applied, this kind of stone cutting machine has strong oxidation resistance.

Used in our customer's factory DeliveryFujian JOBORN MACHINERY Co., Ltd.

Tel.: +86-59526929898

Fax: +86-59526566898